INTRODUCTION:

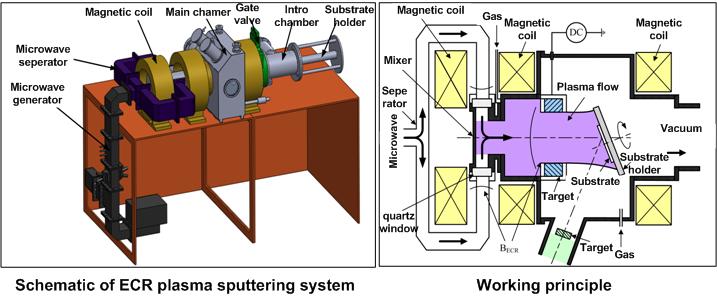

Multi-Functional ECR(electron cyclotron resonance) Nano Surface Processing System consists of the microwave part, ECR plasma sputtering part, gas hose, and the vacuum part. The system can realize the preparation of thin solid films with electron and ion irradiation, and other nanosurface processing techniques including chemical vapor deposition, ion etching, electron polishing and element doping. Since the multi-functional ECR nano surface processing system owns the merits of electron/ion two irradiation modes and the precise control of substrate irradiation energy and element doping content, the system provides a path to prepare and process new nanosurface with required functions.

SPECIFICATION:

ECR Plasma source

Divergence and Mirror-confinement magnetic field distributions

Microwave power continuously adjustable

Double-sputtering system

Two sputtering target under DC magnetron sputtering discharge

Cylindrical target sputtering power: ≧1500 W

High vacuum chamber

Ultimate vacuum: 3x10-5 Pa

Substrate size: ≧2 inch substrate bias power: ≧750 W

Low vacuum chamber

Ultimate vacuum: 6x10-5 Pa

External controlling system

Magnetic field oscillation: ≦0.5 Oe

Microwave power oscillation: ≦1%

Gas flow rate accuracy: ≦1% of the meter full scale\

Main application

Film preparation with ion irradiation (0-150 ev)

Film preparation with electron irradiation (0-500 ev)

Film preparation with chemical vapor depositon

Plasma etching (0-300 eV)

Electron polishing (0-500 eV)

Element doping (N、H、O、Si、Ti、Pt et al)

High temperature annealing (25 ºC ~750 ºC)