=2020 =

29. Ultrasmooth nanocrystalline carbon film induced by low concentration doping: Carbide disorienting graphene nanocrystallite

Carbon 158 (2020) 69-76 (PDF-File)

Cheng Chen, Xue Fan, Dongfeng Diao*

The fabrication of nanocrystalline films is usually accompanied by undesired surface roughening, which limits their

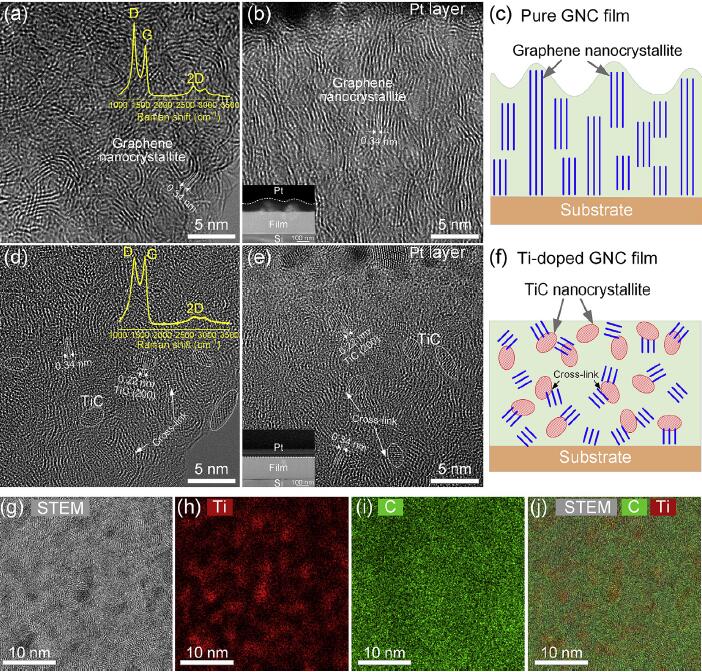

applications in tribology, optics and electronics. Here, we report a technique to reduce the average roughness of graphene nanocrystalline carbon film from 18.3 nm to 0.66 nm by ~5 at.% Tidoping. The surface of the Ti-doped graphene nanocrystalline carbon film stay ultrasmooth from few nanometer thick up to 1 mm thick. Based on the nanostructure characterization, the ultrasmooth mechanism is interpreted that Ti-doping leads to the formation of TieC bond, and changes the growth of graphene nanocrystallite from preferred vertical-aligned orientation to random orientation. The ultrasmooth mechanism is general, as shown by similar effects with low concentration doping of Si, Al, Cr, Zr and W. This approach paves a way for fabricating ultrasmooth nanocrystalline carbon films without a requirement of ion-impact-induced downhill current, and significantly improving the hardness of the graphene nanocrystalline carbon film.

applications in tribology, optics and electronics. Here, we report a technique to reduce the average roughness of graphene nanocrystalline carbon film from 18.3 nm to 0.66 nm by ~5 at.% Tidoping. The surface of the Ti-doped graphene nanocrystalline carbon film stay ultrasmooth from few nanometer thick up to 1 mm thick. Based on the nanostructure characterization, the ultrasmooth mechanism is interpreted that Ti-doping leads to the formation of TieC bond, and changes the growth of graphene nanocrystallite from preferred vertical-aligned orientation to random orientation. The ultrasmooth mechanism is general, as shown by similar effects with low concentration doping of Si, Al, Cr, Zr and W. This approach paves a way for fabricating ultrasmooth nanocrystalline carbon films without a requirement of ion-impact-induced downhill current, and significantly improving the hardness of the graphene nanocrystalline carbon film.

=2019 =

28.Thermally induced atomic and electronic structure evolution in nanostructured carbon film by in situ TEM/EELS analysis

Applied Surface Science 498 (2019) 143831(PDF-File)

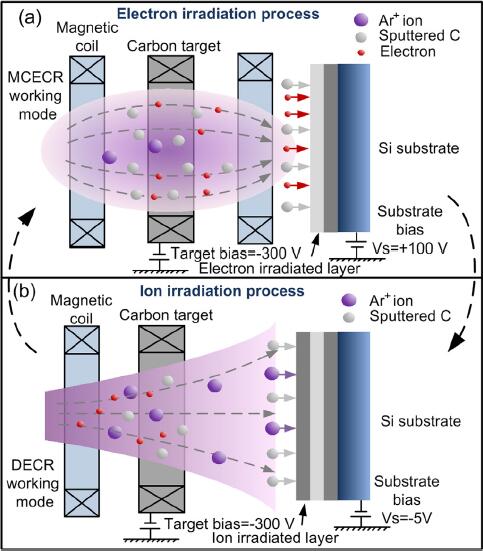

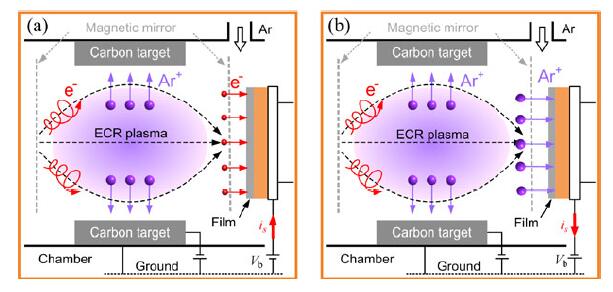

Nan Jiana, Peidong Xue, Dongfeng Diao*

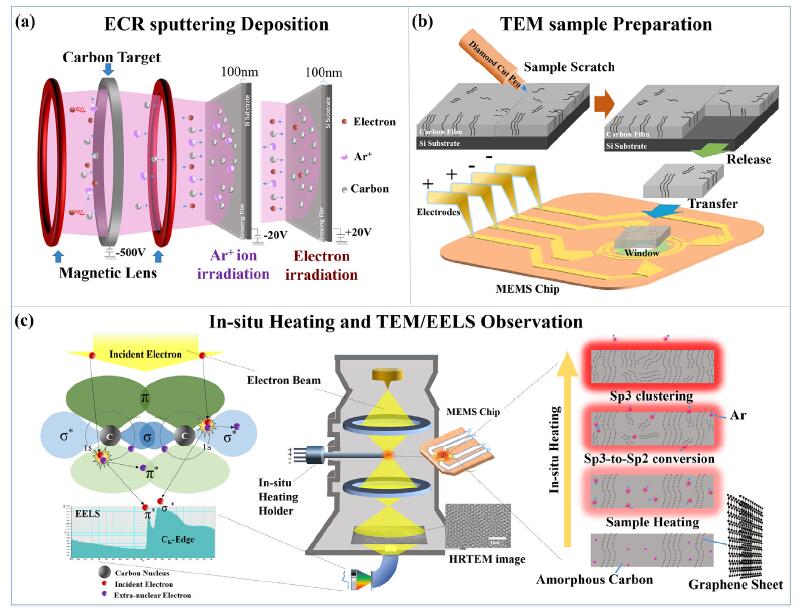

The atomic and electronic structures of nanostructured carbon film are of fundamental importance due to their dominant role in carbon films' physical, chemical and mechanical properties. Here, we reported thermally induced atomic and electronic structure evolution of nanostructured carbon film by in-situ transmission electron microscopy (TEM) and electron energy loss spectroscopy (EELS). Two nanostructured carbon films were synthesized by electron cyclotron resonance (ECR) plasma sputtering under ion and electron irradiation, respectively. We observed that even though the two carbon films had similar initial sp2/sp3 hybridization ratio, they exhibited very different performance during the same heating process. The electron irradiated film only had a relative slight clustering of sp2 carbon crystallites and almost maintained its sp2/sp3 ratio till 1000 °C; while the ion irradiated film had a significant sp2 crystallites clustering, started its sp3-to-sp2 conversion from 200 °C and almost completed at 400 °C. Argon signal was only found in the ion irradiated carbon film and its content reduced simultaneously with the sp3-to-sp2 conversion process. We suggest that the heated argon trapped inside the carbon film were responsible for triggering the sp3-to-sp2 conversion. The result will guide the future application of the nanostructured carbon film in the proper operation temperature range and help to choose appropriate irradiation method for thin film surface modification.

dominant role in carbon films' physical, chemical and mechanical properties. Here, we reported thermally induced atomic and electronic structure evolution of nanostructured carbon film by in-situ transmission electron microscopy (TEM) and electron energy loss spectroscopy (EELS). Two nanostructured carbon films were synthesized by electron cyclotron resonance (ECR) plasma sputtering under ion and electron irradiation, respectively. We observed that even though the two carbon films had similar initial sp2/sp3 hybridization ratio, they exhibited very different performance during the same heating process. The electron irradiated film only had a relative slight clustering of sp2 carbon crystallites and almost maintained its sp2/sp3 ratio till 1000 °C; while the ion irradiated film had a significant sp2 crystallites clustering, started its sp3-to-sp2 conversion from 200 °C and almost completed at 400 °C. Argon signal was only found in the ion irradiated carbon film and its content reduced simultaneously with the sp3-to-sp2 conversion process. We suggest that the heated argon trapped inside the carbon film were responsible for triggering the sp3-to-sp2 conversion. The result will guide the future application of the nanostructured carbon film in the proper operation temperature range and help to choose appropriate irradiation method for thin film surface modification.

27. Structural and tribological behaviors of graphene nanocrystallited carbon nitride films

Applied Surface Science 495 (2019) 143591

Pengfei Wang, Peidong Xue, Cheng Chen, Dongfeng Diao*

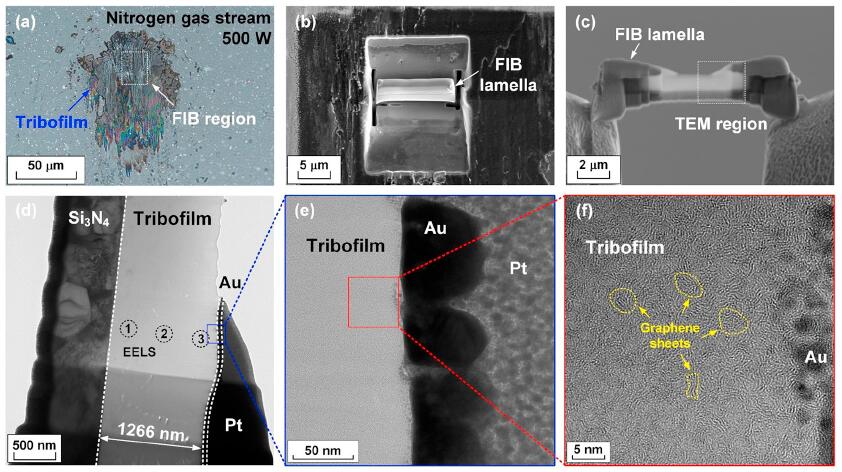

Structural and tribological performances of graphene nanocrystallited carbon nitride (GNCN) films were investigated. The GNCN films were prepared in a multifunctional electron cyclotron resonance plasma system with the variation of the microwave power from 300 to 700 W. An increase in the growth rate and a decrease in the nitrogen atomic concentration were clearly observed with increasing microwave power. Whereas, the residual stress, surface roughness (Ra), and nano-scratch depth of the GNCN films were independent of the microwave power. Raman and XPS characterizations of the GNCN films indicated a gradual increase in sp2 carbon bonding structures as well as the size of the graphene nanocrystallite. When rubbing against the Si3N4 balls, low friction coefficients of approximately 0.05 were achieved in nitrogen gas atmosphere. Low friction was attributed to the formation of a uniform tribofilm on the wear scar of the worn Si3N4 ball surface. TEM-EELS analysis of the transfer film evidenced the formation of graphene nanocrystallites and the loss of nitrogen atoms in the topmost layer. It is strongly argued that the evolution of carbon sp2 structure on the contact interface is favorable for obtaining low friction coefficient of the GNCN films in nitrogen gas environment.

=2018 =

26.Nanosized graphene sheets enhanced electron field emission behavior in pure carbon film

Thin Solid Films 664 (2018) 124–129

Kun Sun, Dongfeng Diao*, Lei Yang, Weiqiang Zhang, Xue Fan

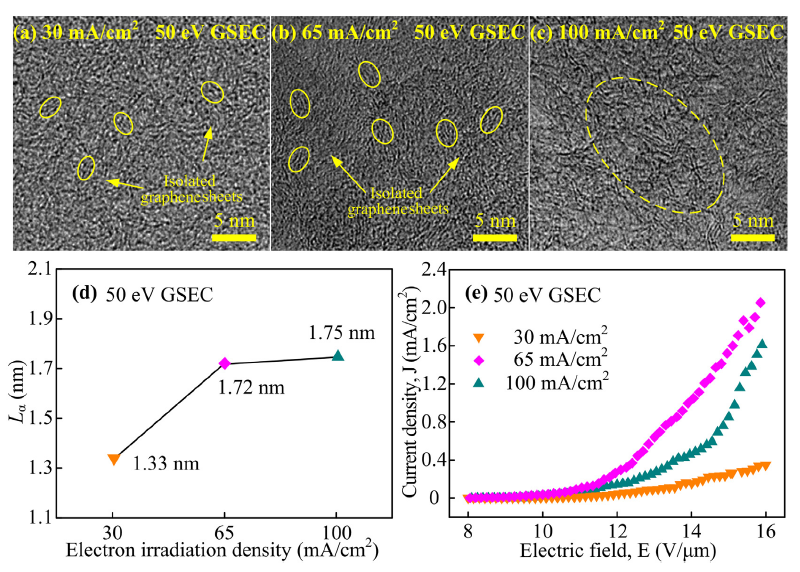

We reported the field emission behavior of pure carbon films deposited by low-energy electron irradiation in electron  cyclotron resonance plasma. First, the field emission behaviors of amorphous, graphene sheets embedded and graphite-like structures were investigated, and the graphene sheets embedded carbon film exhibited an enhanced performance. Then by controlling the electron irradiation energies and densities, the effects of the graphene sheets on the field emission properties were examined. The best electron emission property (turn-on field of 8.4 V/μm and maximum current density of 2.10 mA/cm2 at electric field of 16 V/μm) was obtained with the carbon film under the electron irradiation energy of 50 eV and density of 65 mA/cm2. The mechanism of enhanced field emission was attributed to the nanosized graphene sheets which acted as electron emitters and transport channels. The method of controlling nanosized graphene sheets is important for developing the nanostructured carbon coatings in field emission applications.

cyclotron resonance plasma. First, the field emission behaviors of amorphous, graphene sheets embedded and graphite-like structures were investigated, and the graphene sheets embedded carbon film exhibited an enhanced performance. Then by controlling the electron irradiation energies and densities, the effects of the graphene sheets on the field emission properties were examined. The best electron emission property (turn-on field of 8.4 V/μm and maximum current density of 2.10 mA/cm2 at electric field of 16 V/μm) was obtained with the carbon film under the electron irradiation energy of 50 eV and density of 65 mA/cm2. The mechanism of enhanced field emission was attributed to the nanosized graphene sheets which acted as electron emitters and transport channels. The method of controlling nanosized graphene sheets is important for developing the nanostructured carbon coatings in field emission applications.

25.Ion excitation and etching effects on top-surface properties of sp2 nanocrystallited carbon films

Applied Surface Science 462 (2018) 669–677 (PDF-File)

Xue Fan, Dongfeng Diao*

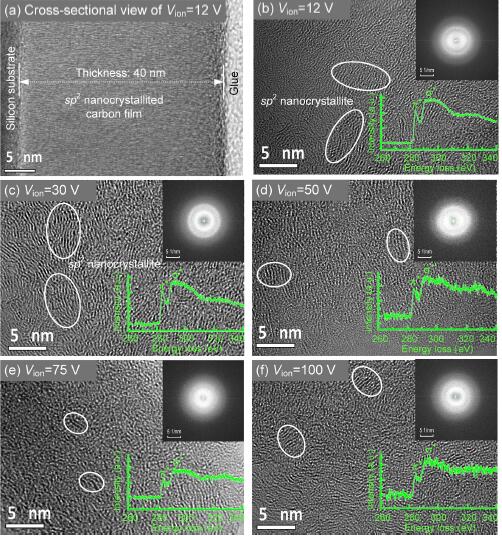

We proposed the low energy ion irradiation effects (ion excitation and ion etching) on the formation and the topsurface properties of sp2 nanocrystallited carbon films in electron cyclotron resonance (ECR) plasma puttering system. In this work, the ion etching rate during film deposition was measured and a threshold voltage for physical etching was found to be about 35 V. Below the threshold voltage, the film growth was induced by ion excitation effect (ion exciting electrons of top-most atoms), as a result, the sp2 dominant nanocrystallite size in the films was large. When the ion energy exceeded the threshold voltage, the film growth was induced by ion etching effect (ion breaking covalent bond), and the nanocrystallite size was small confirmed by the transmission electron microscopy (TEM) observation and Raman analysis. Furthermore, the top-surface properties of sp2 nanocrystallite carbon films prepared with different ion irradiation effects were examined by using the atomic force microscopy (AFM). Results showed that the ion etched carbon films had smaller surface roughness, scratch depth and adhesive force compared with the ion excited carbon films. These findings shed light on the fabrication and applications of carbon based nanostructured materials.

properties of sp2 nanocrystallited carbon films in electron cyclotron resonance (ECR) plasma puttering system. In this work, the ion etching rate during film deposition was measured and a threshold voltage for physical etching was found to be about 35 V. Below the threshold voltage, the film growth was induced by ion excitation effect (ion exciting electrons of top-most atoms), as a result, the sp2 dominant nanocrystallite size in the films was large. When the ion energy exceeded the threshold voltage, the film growth was induced by ion etching effect (ion breaking covalent bond), and the nanocrystallite size was small confirmed by the transmission electron microscopy (TEM) observation and Raman analysis. Furthermore, the top-surface properties of sp2 nanocrystallite carbon films prepared with different ion irradiation effects were examined by using the atomic force microscopy (AFM). Results showed that the ion etched carbon films had smaller surface roughness, scratch depth and adhesive force compared with the ion excited carbon films. These findings shed light on the fabrication and applications of carbon based nanostructured materials.

24.Friction-induced rapid restructuring of graphene nanocrystallite cap layer at sliding surfaces: Short run-in period

Carbon 130 (2018) 215-221(PDF)

Cheng Chen, Peidong Xue, Xue Fan, Chao Wang, Dongfeng Diao*

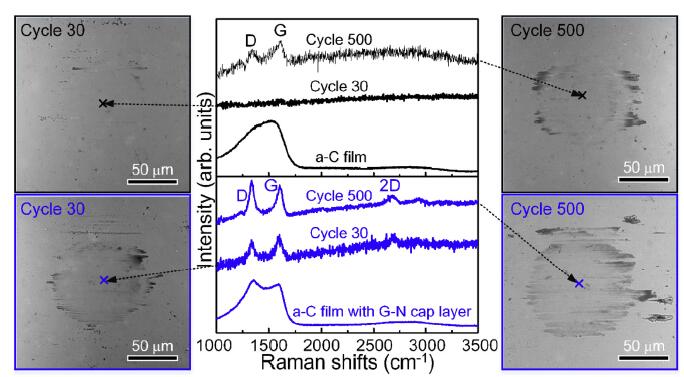

Amorphous carbon film is vastly applied for low-friction protective coatings at contact sliding surfaces. However before reaching steady low friction status, the film always endures a high friction period known as the “run-in” period, sometimes taking thousands of sliding cycles, causing remarkable energy dissipation. Here, we report that the run-in period of amorphous carbon film could be drastically shortened to 22 ± 5 cycles by fabricating a 5-nm graphene nanocrystallite cap layer. The cap layer gave rise to rapid formation of graphene nanocrystallized transfer film, which responds to the short run-in period. We found two key factors for the rapid formation of transfer film. Firstly, the cap layer had lower wear resistance than the amorphous carbon, severing as a quick-wearing sacrificial layer. Secondly, the anocrystallization of transfer film was mainly due to friction-induced restructuring of graphene nanocrystallite but not friction-induced heat. In addition, the friction test of amorphous carbon film covered with multilayer graphene micro-flakes also verified that friction-induced rapid restructuring of graphene sheets at sliding surfaces resulted in short run-in period.

status, the film always endures a high friction period known as the “run-in” period, sometimes taking thousands of sliding cycles, causing remarkable energy dissipation. Here, we report that the run-in period of amorphous carbon film could be drastically shortened to 22 ± 5 cycles by fabricating a 5-nm graphene nanocrystallite cap layer. The cap layer gave rise to rapid formation of graphene nanocrystallized transfer film, which responds to the short run-in period. We found two key factors for the rapid formation of transfer film. Firstly, the cap layer had lower wear resistance than the amorphous carbon, severing as a quick-wearing sacrificial layer. Secondly, the anocrystallization of transfer film was mainly due to friction-induced restructuring of graphene nanocrystallite but not friction-induced heat. In addition, the friction test of amorphous carbon film covered with multilayer graphene micro-flakes also verified that friction-induced rapid restructuring of graphene sheets at sliding surfaces resulted in short run-in period.

=2017 =

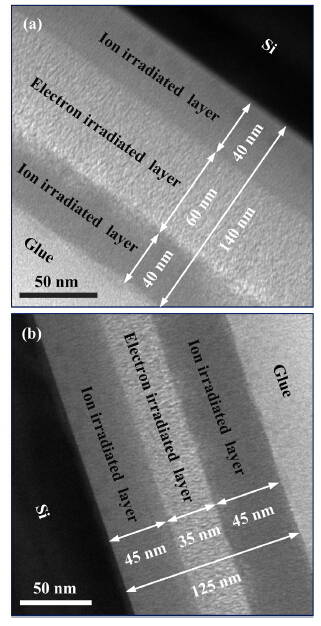

23.Nanocrystalline/amorphous biphase enhanced mechanical properties in multilayer carbon films

Surface & Coatings Technology 334 (2018) 1–6 (薛沛东论文.pdf)

Peidong Xue, Lei Yang, Dongfeng Diao*

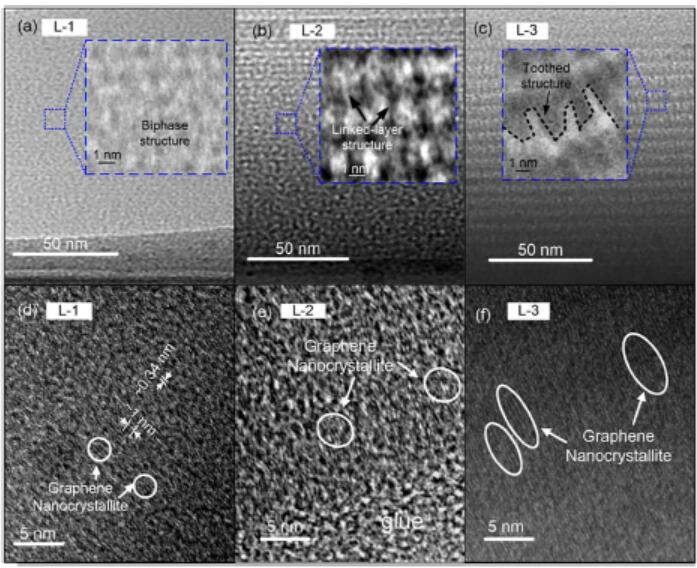

This study reports the nanostructure evolution and mechanical properties improvement in the  nanocrystalline/amorphous multilayer carbon films. Electron cyclotron resonance sputtering and electron/ion alternative irradiation techniques were used to deposit the multilayer carbon films with the total film thicknesses ranging from 130 to 10 nm and the single layer thicknesses ranging from 4 to 1 nm. The high resolution transmission electron microscopy observation showed that the interface between nanocrystalline layer and amorphous layer evolved from an original toothed structure to a mixed biphase structure, and the nanocrystallite size in nanocrystalline layer decreased when layer thickness was reduced from 4 to 1 nm. The nano-indenter tests showed a significant improvement in hardness of multilayer film when single layer thickness was reduced from 4 to 1 nm. The scratch tests revealed that good scratch resistance could be preserved in the multilayer film with 1 nm single layer thickness when total film thickness was only 10 nm. This work may shed light on the ultrathin multilayered coating technology.

nanocrystalline/amorphous multilayer carbon films. Electron cyclotron resonance sputtering and electron/ion alternative irradiation techniques were used to deposit the multilayer carbon films with the total film thicknesses ranging from 130 to 10 nm and the single layer thicknesses ranging from 4 to 1 nm. The high resolution transmission electron microscopy observation showed that the interface between nanocrystalline layer and amorphous layer evolved from an original toothed structure to a mixed biphase structure, and the nanocrystallite size in nanocrystalline layer decreased when layer thickness was reduced from 4 to 1 nm. The nano-indenter tests showed a significant improvement in hardness of multilayer film when single layer thickness was reduced from 4 to 1 nm. The scratch tests revealed that good scratch resistance could be preserved in the multilayer film with 1 nm single layer thickness when total film thickness was only 10 nm. This work may shed light on the ultrathin multilayered coating technology.

22.Low friction of graphene nanocrystallite embedded carbon nitride coatings prepared with MCECR plasma sputtering

Surface & Coatings Technology 332 (2017) 153–160

Pengfei Wang, Weiqiang Zhang, Dongfeng Diao*

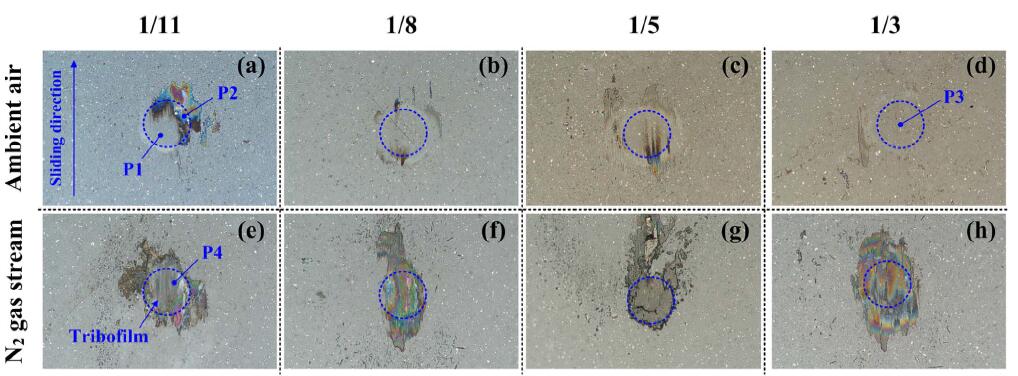

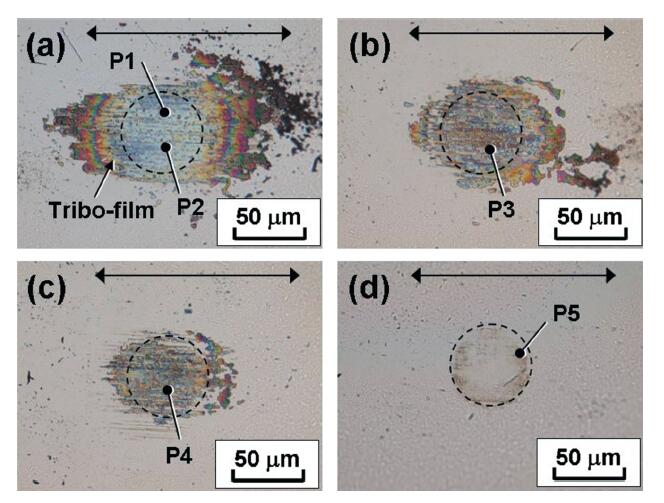

Graphene nanocrystallite embedded carbon nitride (GNECN) coatings were fabricated with the mirror confinement electron  cyclotron resonance (MCECR) plasma sputtering system under low energy electron irradiation at various N2/Ar ratios. N2/Ar ratio was clarified to be an effective deposition parameter for tailoring the composition and structure of the GNECN coatings. It was observed that the deposition rate, N/C atomic ratio, internal stress, surface roughness, and scratch depth of the prepared GNECN coatings change greatly with the increasing N2/Ar ratio from 1/11 to 1/3. Graphene nanocrystallite was clearly identified in the amorphous carbon nitride structure from the analyses of TEM, XPS, and Raman spectroscopy. Moreover, the friction behavior of the GNECN coatings sliding against Si3N4 balls in both ambient air and N2 gas stream showed less dependency on the N2/Ar ratio. Specifically, high friction coefficients ranging from 0.10 to 0.15 were obtained in ambient air, whereas, stable and low friction coefficients of< 0.05 were achieved in N2 gas stream. Optical images and Raman spectra of the worn surfaces on the Si3N4 balls and GNECN coatings suggested that a homogeneous tribofilm on the mating ball surface together with the generation and evolution of the nano-size graphene structure in the GNECN coating are the key points in achieving stable and low friction coefficients of< 0.05 of the GNECN coatings in N2 gas stream. Finally, it was argued that the combination of low energy electron irradiation and nitrogen atom incorporation in the MCECR plasma sputtering system results in the embedding of soft graphene nanocrystallites into hard carbon nitride matrix, providing a beneficial architecture for achieving stable and low friction coefficients of GNECN coatings in N2 gas stream.

cyclotron resonance (MCECR) plasma sputtering system under low energy electron irradiation at various N2/Ar ratios. N2/Ar ratio was clarified to be an effective deposition parameter for tailoring the composition and structure of the GNECN coatings. It was observed that the deposition rate, N/C atomic ratio, internal stress, surface roughness, and scratch depth of the prepared GNECN coatings change greatly with the increasing N2/Ar ratio from 1/11 to 1/3. Graphene nanocrystallite was clearly identified in the amorphous carbon nitride structure from the analyses of TEM, XPS, and Raman spectroscopy. Moreover, the friction behavior of the GNECN coatings sliding against Si3N4 balls in both ambient air and N2 gas stream showed less dependency on the N2/Ar ratio. Specifically, high friction coefficients ranging from 0.10 to 0.15 were obtained in ambient air, whereas, stable and low friction coefficients of< 0.05 were achieved in N2 gas stream. Optical images and Raman spectra of the worn surfaces on the Si3N4 balls and GNECN coatings suggested that a homogeneous tribofilm on the mating ball surface together with the generation and evolution of the nano-size graphene structure in the GNECN coating are the key points in achieving stable and low friction coefficients of< 0.05 of the GNECN coatings in N2 gas stream. Finally, it was argued that the combination of low energy electron irradiation and nitrogen atom incorporation in the MCECR plasma sputtering system results in the embedding of soft graphene nanocrystallites into hard carbon nitride matrix, providing a beneficial architecture for achieving stable and low friction coefficients of GNECN coatings in N2 gas stream.

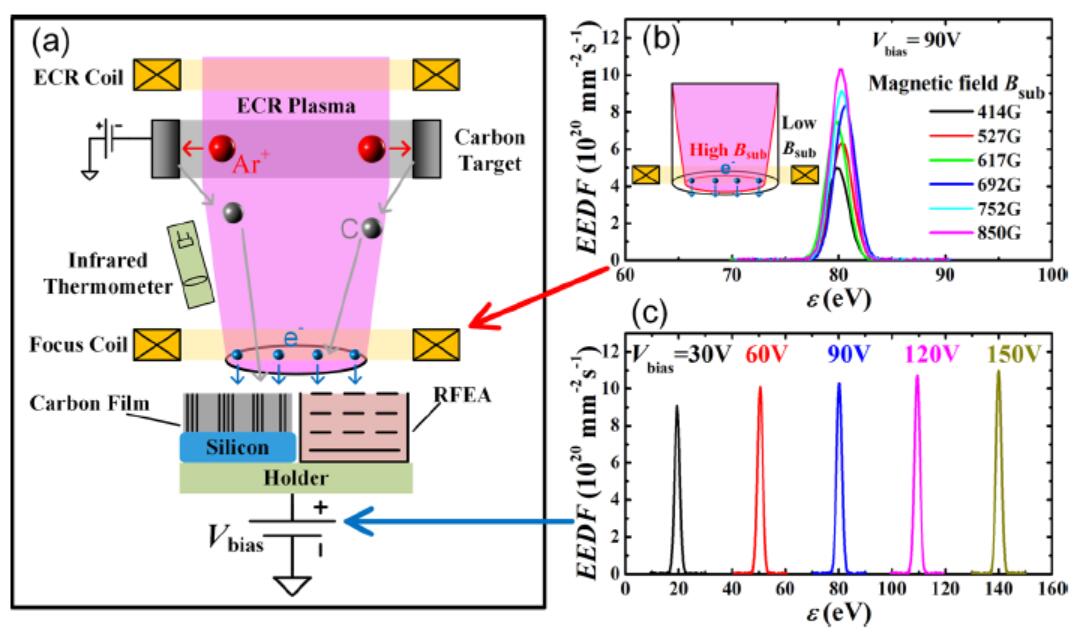

21. Low-energy electron excitation effect on formation of graphene nanocrystallites during

carbon film growth process

Appl. Phys. Lett. 111, 114105 (2017)

Wencong Chen, Xi Zhang, and Dongfeng Diao

We report a low-energy electron excitation effect on the formation of graphene nanocrystallites

embedded in carbon films in an electron cyclotron resonance plasma. In this work, carbon films were deposited at different irradiation electron energies and fluxes monitored using a retarding field energy analyzer, while the deposition temperature was measured using an infrared thermometer. We found that the size and concentration of graphene nanocrystallites strongly depend on the irradiation electron energy and the electron flux but not the temperature, which indicates that the electron excitation effect of the covalent bonds dominates the formation process of these nanocrystallites. This finding shed light on the new fabrication method of 2D materials.

=2016 =

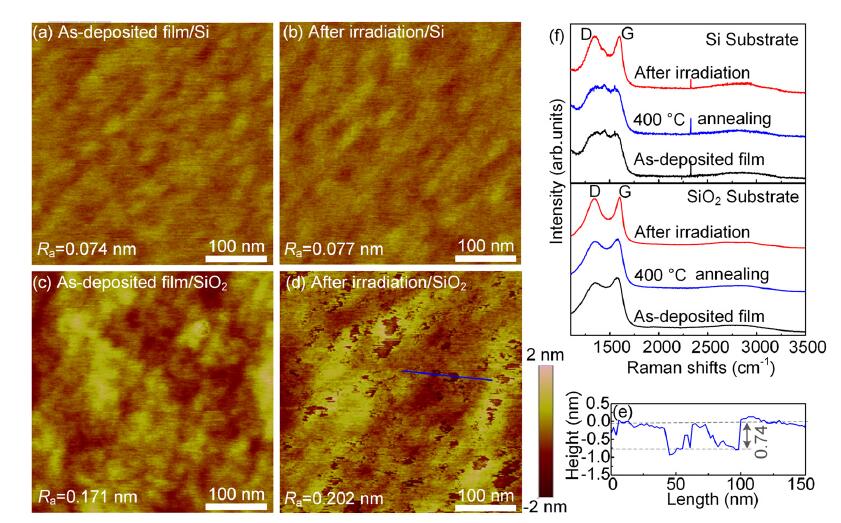

20. Low energy electron irradiation induced carbon etching: Triggering carbon film reacting with oxygen from SiO2 substrate

Applied Physics Letters 109(2016), 053104

Cheng Chen,Chao Wang, and Dongfeng Diao

We report low-energy (50–200 eV) electron irradiation induced etching of thin carbon films on a SiO2 substrate. The etching mechanism was interpreted that electron irradiation stimulated the dissociation of the carbon film and SiO2, and then triggered the carbon film reacting with oxygen from the SiO2 substrate. A requirement for triggering the etching of the carbon film is that the incident electron penetrates through the whole carbon film, which is related to both irradiation energy and film thickness. This study provides a convenient electron-assisted etching with the precursor substrate, which sheds light on an efficient pathway to the fabrication of nanodevices and nanosurfaces.

19. Top surface modification of carbon film on its structure,morphology and electrical resistivity using electron-ion hybrid irradiation in ECR plasma

Surface & Coatings Technology 308 (2016) 50–56

ChaoWang, Cheng Chen, Dongfeng Diao

A two-step electron-ion hybrid irradiation process in electron cyclotron resonance (ECR) plasma was proposed as a flexible method to obtain  carbon film with low roughness and electrical conductive surface. By the combination of either electron irradiation or ion irradiation during and after film deposition, two modes of hybrid irradiation were realized: In i-e hybrid mode, smooth amorphous carbon film was firstly deposited under ion irradiation, and its electrical resistivity was reduced from 1.4 to 0.12 Ω·cm−1 after 5-min electron irradiation. In e-i hybridmode, conductive graphene nanocrystallited film was firstly deposited, and its surface Ra roughness was decreased from 15.7 to 0.063 nm after 5-min ion irradiation. The top surface structural transition under electron irradiation in the i-emode were demonstrated by transmission electronmicroscopy (TEM), Raman spectra, X-ray photoelectron spectroscopy (XPS) and atomic forcemicroscopy (AFM), and the effective depth of electron irradiation on carbon film surface were discussed. This study provided a practical route to themassive production of ultra-smooth carbon filmswith novel nanostructure and outstanding physical properties for potential applications in nano-machinery and nano-devices. The hybrid irradiationmethod also expanded theway of plasma utilization in the fields of film deposition and surface modification, and will inspire various new films and coatings with improved top surfaces.

carbon film with low roughness and electrical conductive surface. By the combination of either electron irradiation or ion irradiation during and after film deposition, two modes of hybrid irradiation were realized: In i-e hybrid mode, smooth amorphous carbon film was firstly deposited under ion irradiation, and its electrical resistivity was reduced from 1.4 to 0.12 Ω·cm−1 after 5-min electron irradiation. In e-i hybridmode, conductive graphene nanocrystallited film was firstly deposited, and its surface Ra roughness was decreased from 15.7 to 0.063 nm after 5-min ion irradiation. The top surface structural transition under electron irradiation in the i-emode were demonstrated by transmission electronmicroscopy (TEM), Raman spectra, X-ray photoelectron spectroscopy (XPS) and atomic forcemicroscopy (AFM), and the effective depth of electron irradiation on carbon film surface were discussed. This study provided a practical route to themassive production of ultra-smooth carbon filmswith novel nanostructure and outstanding physical properties for potential applications in nano-machinery and nano-devices. The hybrid irradiationmethod also expanded theway of plasma utilization in the fields of film deposition and surface modification, and will inspire various new films and coatings with improved top surfaces.

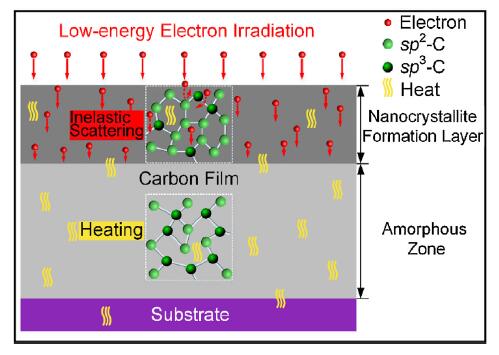

18.Low-energy electron irradiation induced top-surface nanocrystallization of amorphous carbon film

Applied Surface Science 384 (2016) 341–347

Cheng Chena,b, Xue Fana, *, Dongfeng Diao, *

We report a low-energy electron irradiation method to nanocrystallize the top-surface of amorphouscarbon  film in electron cyclotron resonance plasma system. The nanostructure evolution of the carbonfilm as a function of electron irradiation density and time was examined by transmission electron micro-scope (TEM) and Raman spectroscopy. The results showed that the electron irradiation gave rise to theformation of sp2nanocrystallites in the film top-surface within 4 nm thickness. The formation of sp2nanocrystallite was ascribed to the inelastic electron scattering in the top-surface of carbon film. Thefrictional property of low-energy electron irradiated film was measured by a pin-on-disk tribometer.The sp2nanocrystallized top-surface induced a lower friction coefficient than that of the original pureamorphous film. This method enables a convenient nanocrystallization of amorphous surface.

film in electron cyclotron resonance plasma system. The nanostructure evolution of the carbonfilm as a function of electron irradiation density and time was examined by transmission electron micro-scope (TEM) and Raman spectroscopy. The results showed that the electron irradiation gave rise to theformation of sp2nanocrystallites in the film top-surface within 4 nm thickness. The formation of sp2nanocrystallite was ascribed to the inelastic electron scattering in the top-surface of carbon film. Thefrictional property of low-energy electron irradiated film was measured by a pin-on-disk tribometer.The sp2nanocrystallized top-surface induced a lower friction coefficient than that of the original pureamorphous film. This method enables a convenient nanocrystallization of amorphous surface.

17. ECR sputtering and electron/ion alternative irradiation for multilayer carbon films fabrication with tunable layer thickness

Surface & Coatings Technology 296 (2016), 26–32

Peidong Xue, Lei Yang*, Dongfeng Diao*

In this work, we proposed a method of electron cyclotron resonance (ECR) sputtering and electron/ion alternative irradiation to formmultilayer carbon filmswith different single layer thicknesses. The soft electron irradiated layers and protective ion irradiated layers were deposited as the component layers. The transmission electron microscopy (TEM) and Raman spectra proved that the graphene sheets structure in electron irradiated layers could be preserved in multilayer carbon films. We found a rule of the dependence of the surface roughness, mechanical and tribological properties of themultilayer films on the single layer thickness. With the decrease of single layer thickness, the surface roughness decreased and the mechanical and tribological properties improved notably. The mechanisms of the long wear life with low friction coefficient were further discussed based on the hardness enhancement and the cracking length limitation. This work indicated that by decreasing the single layer thickness, ECR sputtering and electron/ion alternative irradiation can fabricate films with combined properties of the component materials, which can be expected for broad nanolayered surface science and engineering applications.

=2015 =

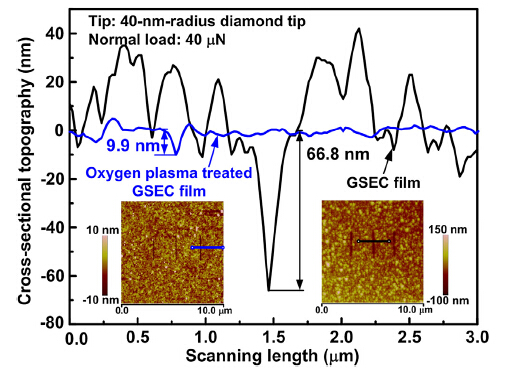

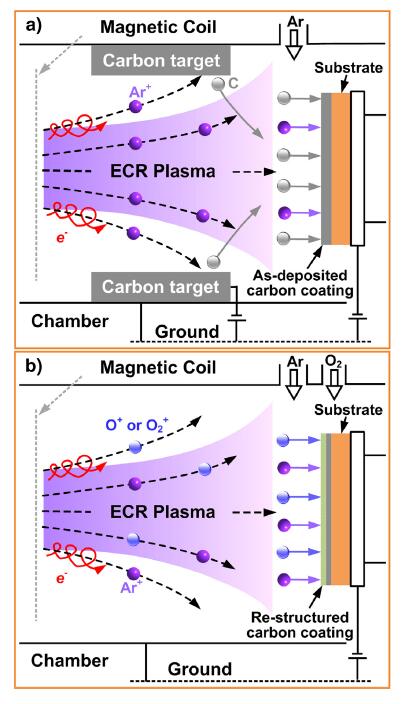

16. Restructured graphene sheets embedded carbon film by oxygen plasma etching and its tribological properties

Applied Surface Science 357 (2015) 771–776(PDF-File)

Meiling Guo, Dongfeng Diao*, Lei Yang, Xue Fan

An oxygen plasma etching technique was introduced for improving the tribological properties of thegraphene sheets embedded carbon (GSEC) film in electron cyclotron resonance plasma processing system. The nanostructural changing in the film caused by oxygen plasma etching was examined by transmission electron microscope, Raman spectroscopy and X-ray photoelectron spectroscopy, showing that the 3 nm thick top surface layer was restructured with smaller graphene nanocrystallite size as well as higher sp3bond fraction. The surface roughness, mechanical behavior and tribological properties of the original GSECand oxygen plasma treated GSEC films were compared. The results indicated that after the oxygen plasma treatment, the average roughness decreased from 20.8 ± 1.1 nm to 1.9 ± 0.1 nm, the hardness increased from 2.3 ± 0.1 GPa to 2.9 ± 0.1 GPa, the nanoscratch depth decreased from 64.5 ± 5.4 nm to 9.9 ± 0.9 nm,and the wear life increased from 930 ± 390 cycles to more than 15,000 frictional cycles. The origin of the improved tribological behavior was ascribed to the 3 nm thick graphene nanocrystallite film. This finding can be expected for wide applications in nanoscale surface engineering.

embedded carbon (GSEC) film in electron cyclotron resonance plasma processing system. The nanostructural changing in the film caused by oxygen plasma etching was examined by transmission electron microscope, Raman spectroscopy and X-ray photoelectron spectroscopy, showing that the 3 nm thick top surface layer was restructured with smaller graphene nanocrystallite size as well as higher sp3bond fraction. The surface roughness, mechanical behavior and tribological properties of the original GSECand oxygen plasma treated GSEC films were compared. The results indicated that after the oxygen plasma treatment, the average roughness decreased from 20.8 ± 1.1 nm to 1.9 ± 0.1 nm, the hardness increased from 2.3 ± 0.1 GPa to 2.9 ± 0.1 GPa, the nanoscratch depth decreased from 64.5 ± 5.4 nm to 9.9 ± 0.9 nm,and the wear life increased from 930 ± 390 cycles to more than 15,000 frictional cycles. The origin of the improved tribological behavior was ascribed to the 3 nm thick graphene nanocrystallite film. This finding can be expected for wide applications in nanoscale surface engineering.

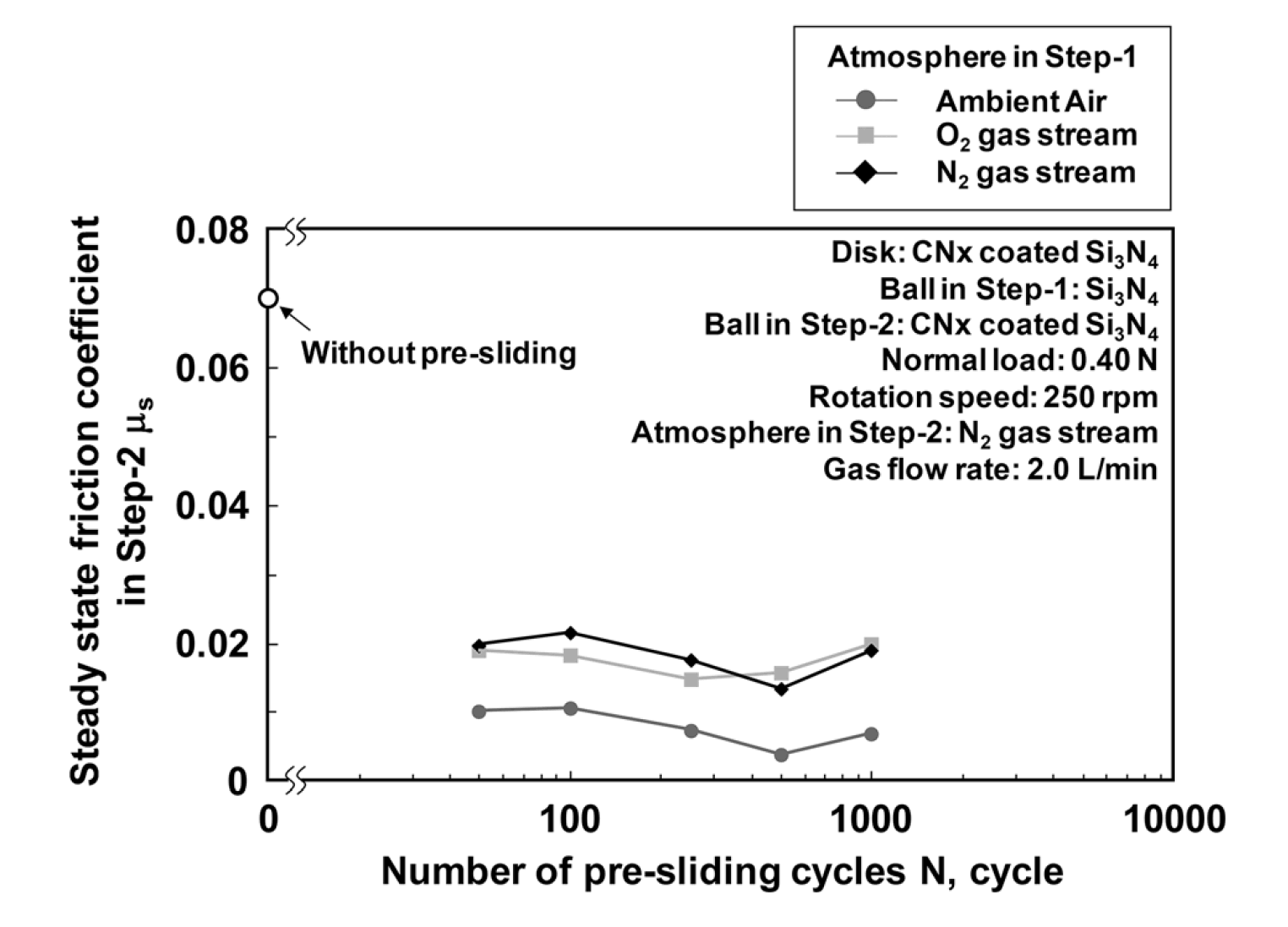

15. Stable and super-low friction of amorphous carbon nitride coatings in nitrogen gas by using two-step ball-on-disk friction test

Lubrication Science 27(2015), 137–149(PDF-File)

Pengfei Wang*, Masakatsu Sugo and Koshi Adachi

Effect of running-in process on friction behaviour of carbon nitride (CNx) coating in N2 gas stream was investigated with a newly introduced two-step ball-on-disk friction test, where the rubbed Si3N4 ball in the pre-sliding (step 1) was replaced by a new CNx-coated Si3N4 ball in the subsequent sliding stage under N2 gas (step 2). The two-step friction test is clarified to be a simple but effective technique for obtaining contact material combination of self-mated CNx coatings and for achieving stable and low frictions of CNx coatings. Friction coefficients of CNx/CNx in N2 gas stream decrease greatly from 0.07 without pre-sliding to less than 0.025 in two-step friction tests. The minimum friction coefficient of 0.004 was obtained by introducing 500 cycles of pre-sliding in ambient air. These stable and low frictions are attributed to the generation of self-mated CNx coatings and the formation of a lubricious layer on the disk surface.

14. Three-layered sandwich structured carbon film prepared by sputtering and ion/electron/ion alternative irradiation

Surface & Coatings Technology 278 (2015), 12-17(PDF-File)

Wenlei Zhang, Dongfeng Diao*, Xue Fan

The electron irradiated carbon film based on electron cyclotron resonance (ECR) sputtering technology has been proved tohave both high conductivity and paramagnetism. However, the relatively low hardness, wear life and high surface roughness value limit its application in Micro-electromechanical Systems (MEMS). To improve these properties, the sandwich structured carbon films with different modulation ratios were introduced on silicon (100) wafers by alternative irradiation (ion/electron/ion) technique in ECR sputtering system. The three-layered anostructure of films was measured with a transmission electron microscopy (TEM). The surface roughness of the film can be controlled to 0.19 nm according to the measurement of atomic force microscope (AFM). The unique characteristics of electron irradiated layer remained stable after irradiation through the analyzing of Raman spectroscopy. The mechanical properties (including hardness, elastic modulus, fracture behavior) and wear life were improved significantly due to the sandwich structure. The results showed that the sandwich structured carbon film is a kind of functional material equipped with enhanced mechanical and tribological properties.

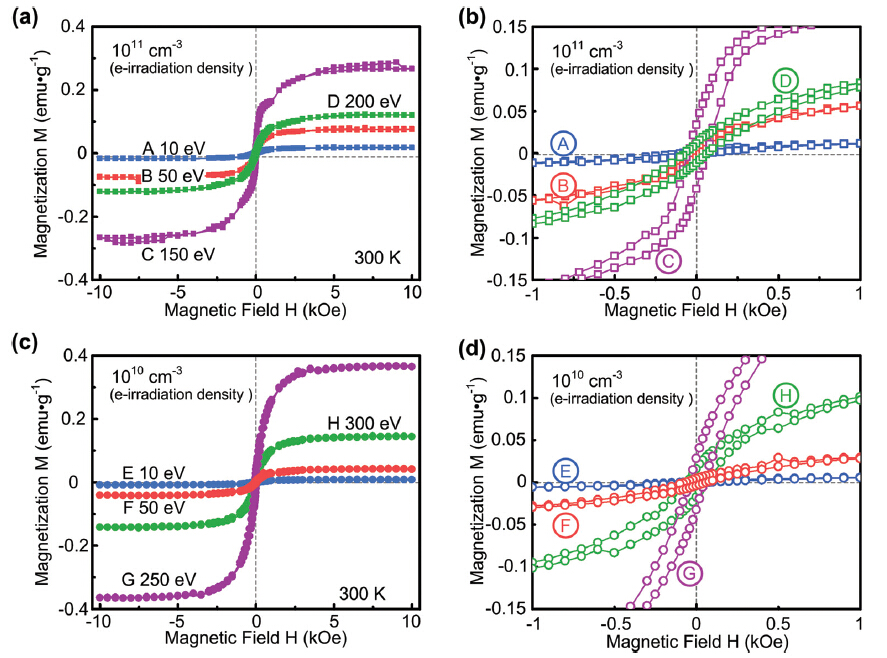

13. Nanosized graphene crystallite induced strong magnetism in pure carbon films

Nanoscale 7 (2015) 4475-4481 (PDF-File)

Chao Wang, Xi Zhang and Dongfeng Diao*

We report strong magnetism in pure carbon films grown by electron irradiation assisted physical vapor deposition in electron cyclotron resonance plasma. The development of graphene nanocrystallites in the amorphous film matrix, and the dependence of the magnetic behavior on amorphous, nanocrystallite and graphite-like structures were investigated. Results were that the amorphous structure shows weak paramagnetism, graphene nanocrystallites lead to strong magnetization, and graphite-like structures corresponded with a lower magnetization. At a room temperature of 300 K, the highest saturation magnetization of 0.37 emu g−1 was found in the nanosized graphene nanocrystallite structure. The origin of strong magnetism in nanocrystallites was ascribed to the spin magnetic moment at the graphene layer edges.

in electron cyclotron resonance plasma. The development of graphene nanocrystallites in the amorphous film matrix, and the dependence of the magnetic behavior on amorphous, nanocrystallite and graphite-like structures were investigated. Results were that the amorphous structure shows weak paramagnetism, graphene nanocrystallites lead to strong magnetization, and graphite-like structures corresponded with a lower magnetization. At a room temperature of 300 K, the highest saturation magnetization of 0.37 emu g−1 was found in the nanosized graphene nanocrystallite structure. The origin of strong magnetism in nanocrystallites was ascribed to the spin magnetic moment at the graphene layer edges.

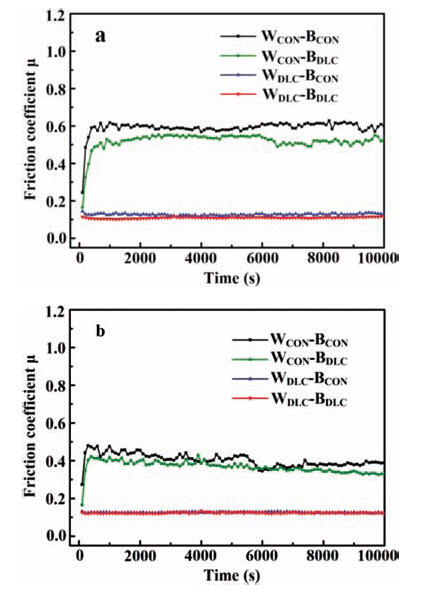

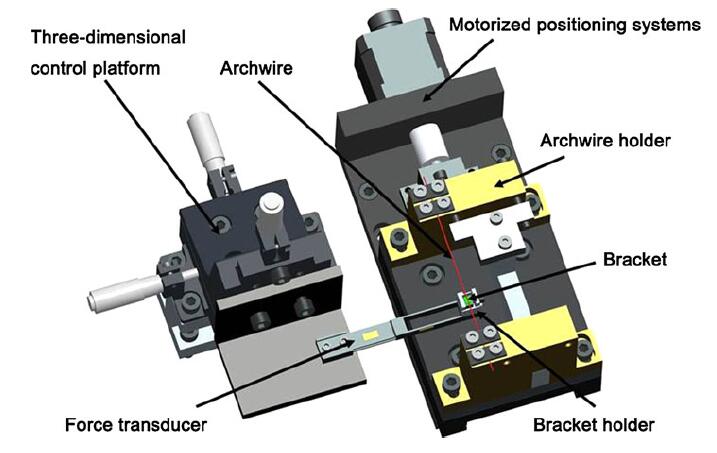

12.The Effects of Diamond-Like Carbon Films on Fretting Wear Behavior of Orthodontic Archwire-Bracket Contacts

Journal of Nanoscience and Nanotechnology 15(2015) 4641–4647 (PDF-File)

Ting Kang, Shi-You Huang, Jie-Jie Huang, Qi-Hong Li, Dong-Feng Diao∗, and Yin-Zhong Duan∗

This study aims to assess the effects of diamond-like carbon (DLC) films on fretting wear behavior of orthodontic archwire-bracket contacts. ‘Mirror-confinement-type electron cyclotron resonance (MCECR) plasma sputtering’ was utilized to deposit carbon films on stainless steel archwires and brackets. Nanostructure of carbon films such as the bonding structure, cross-sectional thickness and surface roughness were studied. The fretting wear behavior of various archwire-bracket contacts were investigated by using a self-developed tester in ambient air and artificial saliva. The results indicated that DLC-coated wires showed significantly low friction coefficient than the uncoated wires independently of the applied environments. Nevertheless, the DLC-coated and uncoated brackets showed no significant differences in the friction coefficient. Microscopic analysis showed that low wear took place for the DLC-coated surfaces. It is proposed that the application of DLC coating on archwires can decrease the orthodontic fretting wear and coefficient of friction. Unfortunately it does not affect the frictional properties for brackets at present.

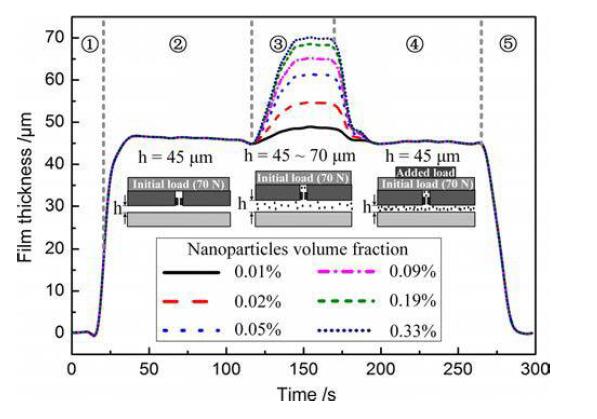

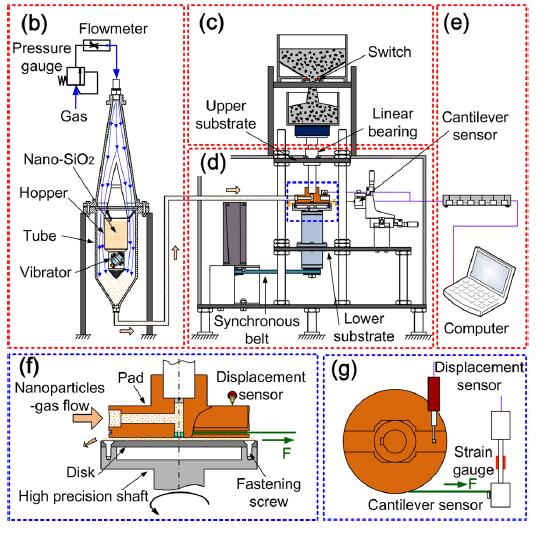

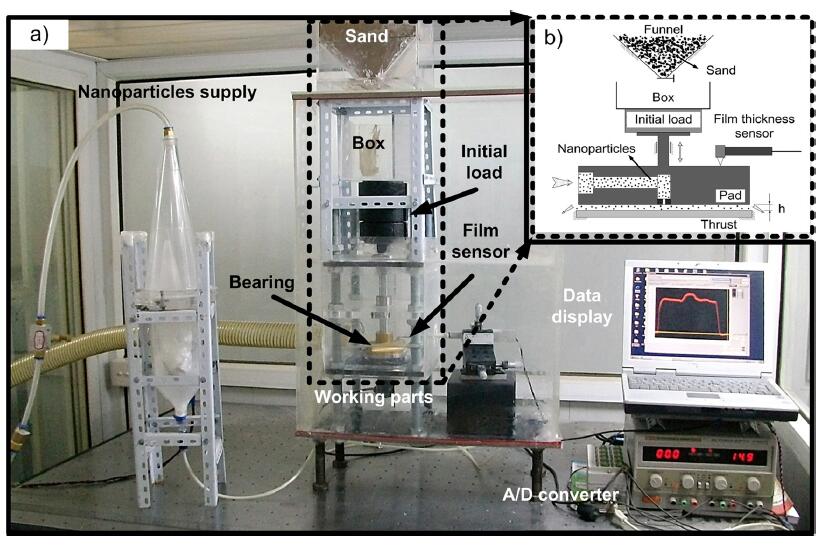

11.Experimental study on load capacity of nanoparticles-laden gas film in thrust bearing

Industrial Lubrication and Tribology,67(3),233–239(2015)

Zhiru Yang, Dongfeng Diao, Hongyan Fan,Xue Fan and Chao Wang

Purpose – The purpose of this paper is to study the load capacity of nanoparticles-laden gas film (NLGF) in thrust bearing.

Design/methodology/approach – SiO2 nanoparticles were added into gas to form an NLGF. The nanoparticles volume fraction in the film was controlled by a vibrator. The film thickness and the film pressure were measured by a micro cantilever displacement sensor and a membrane pressure sensor, respectively. The total load that makes the film thickness keeping constant was quantified, and then, the film load capacity was obtained.

Findings – The investigation shows that nanoparticles can enlarge the film load capacity remarkably; even a little amount of nanoparticles (0.01 per cent) could lead to a sharp rise. With the increase of nanoparticles volume fraction, load capacity increases. However, the increment of load capacity decreases gradually. In addition, the film pressure variation proves the enhancement effect of nanoparticles on the film load capacity.

Research limitations/implications – The paper is restricted to the findings based on NLGF, which is formed by dispersing SiO2 nanoparticles in gas film as an additive. The experimental results are applicable within the range of nanoparticles volume fraction of 0.01-0.33 per cent.

Originality/value – The fact that nanoparticles could enlarge the gas film load capacity is verified by experiment for the first time. This study reveals the corresponding relation between nanoparticles volume fraction and the film load capacity.

=2014 =

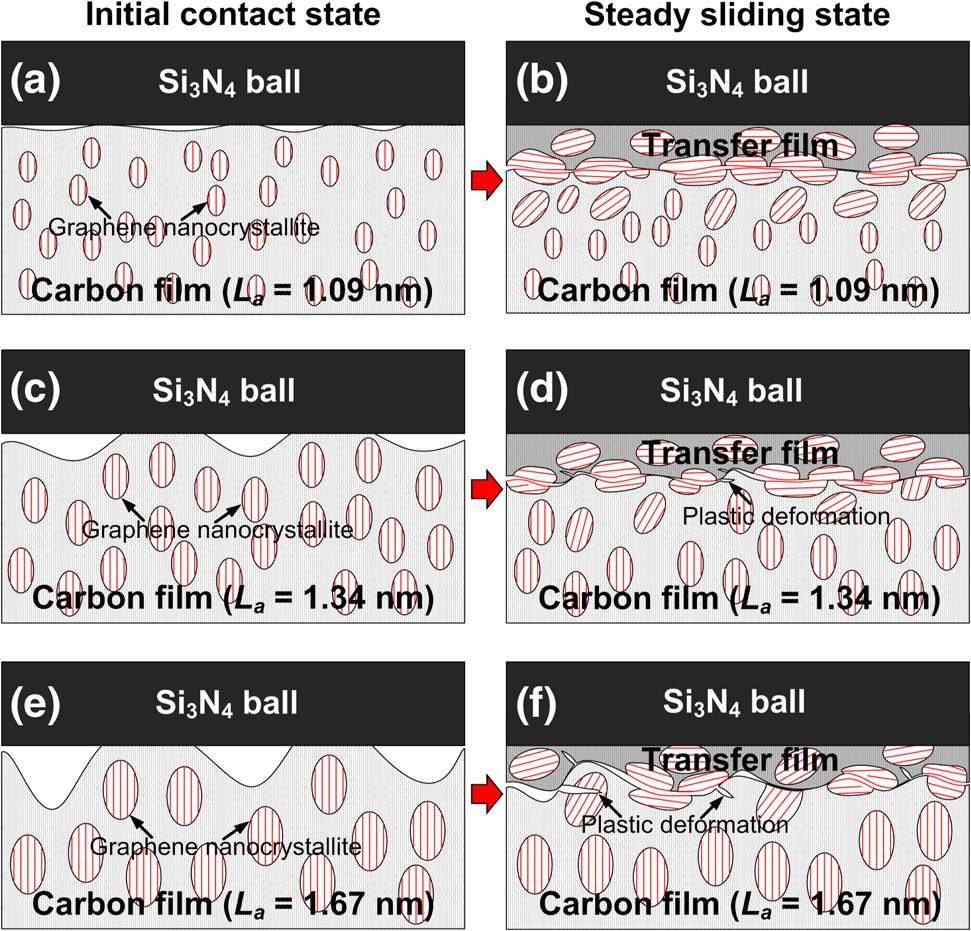

10. Frictional behavior of carbon film embedded with controlling-sized graphene nanocrystallites

Tribology Letters, 55, 429(2014)(PDF-File)

Cheng Chen, Dongfeng Diao*, Xue Fan, Lei Yang and Chao Wang

Graphene nanocrystallites embedded in amorphous carbon matrix can bring excellent tribological, electrical andmagnetical properties to the carbon  films. But too large size of graphene nanocrystallite would lead to degradation of the tribological performance. So it is necessary to clarify the dependence of frictional behavior of the carbon film on graphene nanocrystallite size. In order to control the size, different electron irradiation densities were introduced during film growth in the electron cyclotron resonance plasma sputtering process. Frictional tests on the films were carried out with a Pin-on-Disk tribometer. The evolution of graphene nanocrystallite size along with electron irradiation density was examined by transmission electron microscopy and Raman spectroscopy. The results showed that the graphene nanocrystallite size increased with increasing of the electron irradiation density. The film with a graphene nanocrystallite size of 1.09 nm exhibited a low friction coefficient of 0.03 and a long wear life. When nanocrystallite size increased, the friction coefficient increased and the wear life decreased. Observation on transfer film revealed that the nanocrystallite in transfer film grew larger when initial size was 1.09 nm, and changed smaller when initial size was 1.67 nm. The results suggested that embedded grapheme nanocrystallite played an important role in the formation of transfer film, the initial size of graphene nanocrystallite strongly affected the frictional behavior of the film, and the graphene nanocrystallite needed to be controlled under a certain size in order to keep the good tribological performance.

films. But too large size of graphene nanocrystallite would lead to degradation of the tribological performance. So it is necessary to clarify the dependence of frictional behavior of the carbon film on graphene nanocrystallite size. In order to control the size, different electron irradiation densities were introduced during film growth in the electron cyclotron resonance plasma sputtering process. Frictional tests on the films were carried out with a Pin-on-Disk tribometer. The evolution of graphene nanocrystallite size along with electron irradiation density was examined by transmission electron microscopy and Raman spectroscopy. The results showed that the graphene nanocrystallite size increased with increasing of the electron irradiation density. The film with a graphene nanocrystallite size of 1.09 nm exhibited a low friction coefficient of 0.03 and a long wear life. When nanocrystallite size increased, the friction coefficient increased and the wear life decreased. Observation on transfer film revealed that the nanocrystallite in transfer film grew larger when initial size was 1.09 nm, and changed smaller when initial size was 1.67 nm. The results suggested that embedded grapheme nanocrystallite played an important role in the formation of transfer film, the initial size of graphene nanocrystallite strongly affected the frictional behavior of the film, and the graphene nanocrystallite needed to be controlled under a certain size in order to keep the good tribological performance.

9. Scratch Behavior of Re-structured Carbon Coating by Oxygen Plasma Etching Technology for Magnetic Disk Application

Surface &Coatings Technology 251, 128 (2014) (PDF-File)

Meiling Guo, Dongfeng Diao*, Xue Fan, Lei Yang, Liwei Yu.

An oxygen plasma etching technology to prepare ultrathin carbon coatings for magnetic disk in electroncyclotron resonance(ECR) plasma system was developed. In the preparation process, as-deposited carbon coatings were etched by oxygen plasma to obtain re-structured carbon coatings. Scratch behaviors of the as-deposited and re-structured carbon coatings on silicon substrates were evaluated by atomic force microscope (AFM) scratch test. It was found that the scratch resistance of the re-structured carbon coating was improved. Then X-ray photoelectron spectroscopy (XPS) analysis showed that after oxygen plasma etching, the C_C (sp2) content decreased from 55% to 17%, the C\C (sp3) content increased from 33% to 58% and the C\O content increased from 7% to 18%. It indicated that the oxygen plasma etching induced the increase of the sp3 bonding carbon, which contributed to the improved scratch resistance. Further transmission electron microscope (TEM) observation was conducted and the rising of the scratch resistance was inferred to be caused by the formation of the interlayer cross-linking after preferentially breaking the sp2 bond. Based on the above results, the ultrathin re-structured carbon coatings by oxygen plasma etching were prepared on uncoated magnetic disk substrates and showed a better scratch behavior and a comparable surface roughness in comparison with the commercial magnetic disk.

8. Effects of substrate bias voltage and target sputtering power on the structural and tribological properties of carbon nitride coatings

Materials Chemistry and Physics, 145,434 (2014) (PDF-File)

Pengfei Wang *, Takanori Takeno, Julien Fontaine, Masami Aono, Koshi Adachi, Hiroyuki Miki, and Toshiyuki Takagi.

Effects of substrate bias voltage and target sputtering power on the structural and tribological properties of carbon nitride (CNx) coatings are investigated. CNx coatings are fabricated by a hybrid coating process with the combination of radio frequency plasma enhanced chemical vapor deposition (RF PECVD) and DC magnetron sputtering at various substrate bias voltage and target sputtering power in the order of

investigated. CNx coatings are fabricated by a hybrid coating process with the combination of radio frequency plasma enhanced chemical vapor deposition (RF PECVD) and DC magnetron sputtering at various substrate bias voltage and target sputtering power in the order of

400 V 200W,400 V 100W,800 V 200W, and800 V 100W. The deposition rate, N/C atomic ratio, and hardness of CNx coatings as well as friction coefficient of CNx coating sliding against AISI 52100 pin in N2 gas stream decrease, while the residual stress of CNx coatings increases with the increase of substrate bias voltage and the decrease of target sputtering power. The highest hardness measured under single stiffness mode of 15.0 GPa and lowest residual stress of 3.7 GPa of CNx coatings are obtained at400 V 200W, whereas the lowest friction coefficient of 0.12 of CNx coatings is achieved at800 V 100W. Raman and XPS analysis suggest that sp3 carbon bonding decreases and sp2 carbon bonding increases with the variations in substrate bias voltage and target sputtering power. Optical images and Raman characterization of worn surfaces confirm that the friction behavior of CNx coatings is controlled by the directly sliding between CNx coating and steel pin. Therefore, the reduction of friction coefficient is attributed to the decrease of sp3 carbon bonding in the CNx coating. It is concluded that substrate bias voltage and target sputtering power are effective parameters for tailoring the structural and tribological properties of CNx coatings.

7. Lubrication Performance of Nanoparticles-Laden Gas Film in Thrust Bearing under Noncontact and Contact Conditions

ASME,Trans., Journal of Tribology 136, 034505(2014) (PDF-File)

Hongyan Fan, Xue Fan, Zhiru Yang and Dongfeng Diao*

The nanoparticles-laden gas film (NLGF), which is formed by adding nanoparticles into the gas film, has a potential toincrease the load capacity of  the gas film and to protect the surfaces of the bearing from severe contact damage. In order to explore the lubrication performance of NLGF, the load capacity in the noncontact state and the friction coefficient in the contact state were studied experimentally by a novel NLGF thrust bearing apparatus. The effects of nanoparticles concentration on the load capacity and the friction coefficient were investigated, respectively. The lubrication performance of NLGF in a 200 start-stop cyclic test was evaluated. The contact surfaces were analyzed by the surface profilometer, scanning electron microscope (SEM), and energy dispersive spectroscopy (EDS). The results showed that NLGF had the enhancement of the load capacity in the noncontact state and possessed the properties of friction reduction and surface protection in the contact state. An optimal nanoparticles concentration of 60 g/m3 was found, making NLGF have a relative high load capacity in the noncontact state and the lowest friction coefficient in the contact state. With the optimal concentration, the friction coefficient with NLGF kept a low value during the 200 start-stop cyclic test. Then the friction reduction mechanism of NLGF was discussed, and it was inferred that the surface of the disk was covered with a protective film formed by nanoparticles, leading to a lower shear force. This study opens new perspectives of adding nanoparticles into gas bearings to improve the lubrication performance.

the gas film and to protect the surfaces of the bearing from severe contact damage. In order to explore the lubrication performance of NLGF, the load capacity in the noncontact state and the friction coefficient in the contact state were studied experimentally by a novel NLGF thrust bearing apparatus. The effects of nanoparticles concentration on the load capacity and the friction coefficient were investigated, respectively. The lubrication performance of NLGF in a 200 start-stop cyclic test was evaluated. The contact surfaces were analyzed by the surface profilometer, scanning electron microscope (SEM), and energy dispersive spectroscopy (EDS). The results showed that NLGF had the enhancement of the load capacity in the noncontact state and possessed the properties of friction reduction and surface protection in the contact state. An optimal nanoparticles concentration of 60 g/m3 was found, making NLGF have a relative high load capacity in the noncontact state and the lowest friction coefficient in the contact state. With the optimal concentration, the friction coefficient with NLGF kept a low value during the 200 start-stop cyclic test. Then the friction reduction mechanism of NLGF was discussed, and it was inferred that the surface of the disk was covered with a protective film formed by nanoparticles, leading to a lower shear force. This study opens new perspectives of adding nanoparticles into gas bearings to improve the lubrication performance.

6. Nanoparticles-Laden Gas Film in Aerostatic Thrust Bearing

ASME,Trans., Journal of Tribology 136, 034501 (2014) (PDF-File)

Zhiru Yang, Dongfeng Diao*, Xue Fan and Hongyan Fan

Nanoparticles-laden gas film (NLGF) was formed by adding SiO2 nanoparticles with volume fraction in the range of 0.014–0.330% and size of 30 nm into the air gas film in a thrust bearing. An effective viscosity of the gas-solid two phase lubrication media was introduced. The pressure distribution in NLGF and the load capacity of the thrust bearing were calculated by using the gassolid two phase flow model with the effective viscosity under the film thicknesses range of 15–60 lm condition. The results showed that the NLGF can increase the load capacity when the film thickness is larger than 30 lm. The mechanism of the enhancement effect of load capacity was attributed to the increase of the effective viscosity of the NLGF from the pure air film, and the novel lubrication media of the NLGF can be expected for the bearing industry application.

=2013 =

5. Coating NiTi archwires with diamond-like carbon films: reducing fluoride-induced corrosion and improving frictional properties

J Mater Sci: Mater Med 24, 2287 (2013)

S.Y. Huang, J.J. Huang, T. Kang, Dongfeng Diao*, and Y.Z. Duan

This study aims to coat diamond-like carbon (DLC) films onto nickel–titanium (NiTi) orthodontic archwires. The film protects against fluoride-induced corrosion and will improve orthodontic friction. ‘Mirror-confinement-type electron cyclotron resonance plasma sputtering’ was utilized to deposit DLC films onto NiTi archwires. The influence of a fluoride-containing environment on the surface topography and the friction force between the brackets and archwires were investigated. The results confirmed the superior nature of the DLC coating, with less surface roughness variation for DLC-coated archwires after immersion in a high fluoride ion environment. Friction tests also showed that applying a DLC coating significantly decreased the fretting wear and the coefficient of friction, both in ambient air and artificial saliva. Thus, DLC coatings are recommended to reduce fluoride-induced corrosion and improve orthodontic friction.

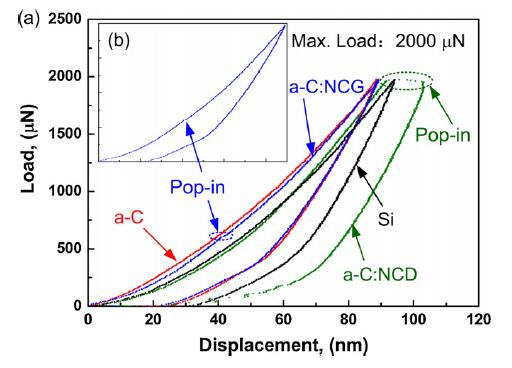

4. Nanoindentation Behavior of Amorphous Carbon Films Containing Nanocrystalline Graphite and Diamond clusters Prepared by Radio Frequency Sputtering

Applied Surface Science 273, 816-823 (2013)

Xue Fan, Dongfeng Diao*, Kenji Nose and T. Yoshida

Amorphous carbon (a-C) films were prepared by a radio-frequency sputtering method. Nano structures in the films werecontrolled by changing the ion irradiation energy and deposition temperature. It was found that nanocrystalline graphite and diamond clusters were embedded in the pure amorphous structure with sizes of approximately 5 nm. a-C films contained nanocrystalline graphite clusters (a-C:NCG) were obtained with the ion energy ranging from 50 to 120 eV and temperature in 300–370 K. a-C film contained nanocrystalline diamond clusters (a-C:NCD) was obtained with 120 eV at 570 K. Nanoindentation behaviors of these carbon films were compared with pure amorphous structured carbon film. The percentage of elastic recoveries of a-C:NCD, a-C, and a-C:NCG films were obtained to be 81.9%, 84.3%, and 87.5%, respectively. Pop-in steps with about 3 nm displacement appeared in loading curves for a-C:NCG film, and 10 nm for a-C:NCD film. These results showed that the nanoindentation behaviors of amorphous carbon film containing cross-linked nanocrystalline graphite clusters is better than that of diamond clusters.

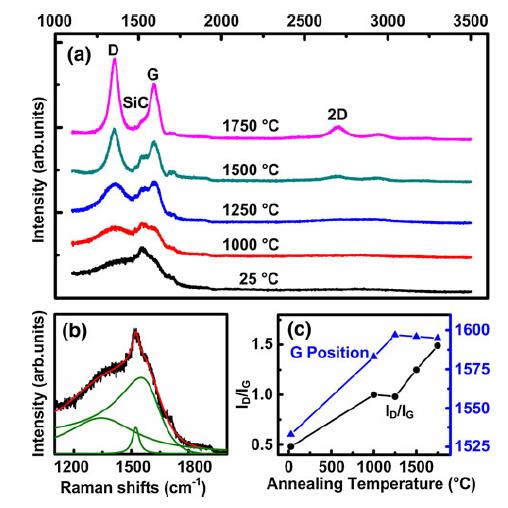

3. Tribological Thermostability of Carbon Film with Vertically Aligned Grapheen Sheets

Tribology Letters 50, 305–311 (2013)

Cheng Chen and Dongfeng Diao*

Tribological thermostability of carbon film with vertically aligned graphene sheets was studied with annealing temperatures up to 1,750 C. The carbon film was deposited on silicon carbide substrate by electron cyclotron resonance plasma sputtering. Tribological thermostabilities of the carbon film in terms of friction coefficient, wear life, and nanoscratch depth were investigated by Pin-on-Disk tribometer and atomic force microscopy. The evolution of nanostructure of vertically aligned graphene sheets in the carbon film as a function of annealing temperature was examined by Raman spectroscopy and transmission electron microscopy. The results showed that the friction coefficient, wear life, and nanoscratch depth of the carbon film were thermally stable up to 1,250 C. When the annealing temperature was 1,500 C, the friction coefficient and the nanoscratch depth increased, the wear life decreased, but still all were of considerable values. These variations were attributed to the initiation of tubular-like structure originated from graphene sheets stacks. After annealing at 1,750 C, tribological performances degraded catastrophically due to the abundant formation of tubular-like structures and the appearance of a graphitic interlayer between the film and the substrate.

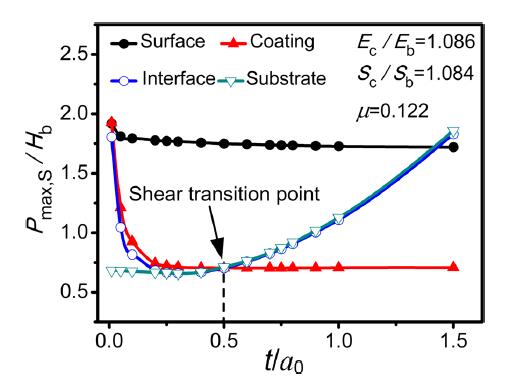

2. Evolution of Maximum Contact Stresses in Amorphous Carbon Coated Silicon During Sliding Wear Against Si3N4 Ball

Tianxiao Cai, Pengyu Zhang and Dongfeng Diao*

ASME,Trans., Journal of Tribology 135, 021401-10 (2013)

The evolution of the maximum contact stresses in amorphous carbon coated silicon during sliding wear against a Si3N4 ball was investigated. Amorphous carbon coating was prepared on a silicon substrate by the electron cyclotron resonance (ECR) plasma sputtering method. Surface morphologies of the coating and counterpart were measured by an atomic force microscope (AFM). The friction and wear behavior of the coating was studied by a ball-on-disk tribometer. The cross-sections of the wear tracks at different wear stages were observed with a scanning electron microscope (SEM). Maximum contact stresses with different coating thicknesses were calculated by the three-dimensional semi-analytical method (SAM). The results demonstrated that when taking surface asperities into consideration, maximum shear stress at the bonding interface and adjacent substrate showed a dramatic increase during wear and should be responsible for the initiation and propagation of the cracks observed at the final stage of sliding.

1. Frictional behavior of nanostructured carbon films

Dongfeng Diao*, Chao Wang, Xue Fan

Friction 1, 63-71(2013)

We propose a new path for preparing nanostructured carbon films (NCFs) by using electron cyclotron resonance (ECR) plasma sputtering with ion–electron hybrid irradiation for controlling the frictional behavior. The frictional behavior of the NCF was measured by using a pin-on-disk tribometer with a nanoprobe displacement sensor, and the transition curves of the friction coefficient and microdisplacement of the NCFs were examined. The friction mechanism was discussed by transmission electron microscopy (TEM) observation on the wear track. From the results, we found a new method to prepare NCFs, which has the potential to achieve low friction at the early stage of sliding contact. In addition, the technology of ECR plasma with ion–electron hybrid irradiation provides a new vision to rebuild a nanostructured surface from an original surface for controlling the frictional behavior.

ion–electron hybrid irradiation for controlling the frictional behavior. The frictional behavior of the NCF was measured by using a pin-on-disk tribometer with a nanoprobe displacement sensor, and the transition curves of the friction coefficient and microdisplacement of the NCFs were examined. The friction mechanism was discussed by transmission electron microscopy (TEM) observation on the wear track. From the results, we found a new method to prepare NCFs, which has the potential to achieve low friction at the early stage of sliding contact. In addition, the technology of ECR plasma with ion–electron hybrid irradiation provides a new vision to rebuild a nanostructured surface from an original surface for controlling the frictional behavior.