Friction-induced rapid restructuring of graphene nanocrystallite cap layer at sliding surfaces: Short run-in periodViews [3808] Delivery time :2018-01-31 11:12:42

Friction-induced rapid restructuring of graphene nanocrystallite cap layer at sliding surfaces: Short run-in period

Carbon 130 (2018) 215-221(PDF-File)

Cheng Chen, Peidong Xue, Xue Fan, Chao Wang, Dongfeng Diao*

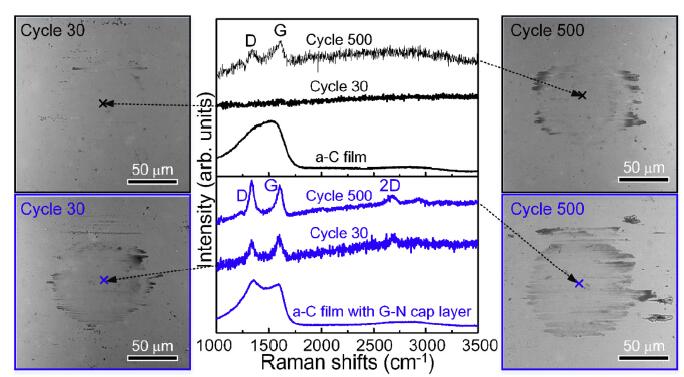

Amorphous carbon film is vastly applied for low-friction protective coatings at contact sliding surfaces. However before reaching steady low friction status, the film always endures a high friction period known as the “run-in” period, sometimes taking thousands of sliding cycles, causing remarkable energy dissipation. Here, we report that the run-in period of amorphous carbon film could be drastically shortened to 22 ± 5 cycles by fabricating a 5-nm graphene nanocrystallite cap layer. The cap layer gave rise to rapid formation of graphene nanocrystallized transfer film, which responds to the short run-in period. We found two key factors for the rapid formation of transfer film. Firstly, the cap layer had lower wear resistance than the amorphous carbon, severing as a quick-wearing sacrificial layer. Secondly, the anocrystallization of transfer film was mainly due to friction-induced restructuring of graphene nanocrystallite but not friction-induced heat. In addition, the friction test of amorphous carbon film covered with multilayer graphene micro-flakes also verified that friction-induced rapid restructuring of graphene sheets at sliding surfaces resulted in short run-in period.

status, the film always endures a high friction period known as the “run-in” period, sometimes taking thousands of sliding cycles, causing remarkable energy dissipation. Here, we report that the run-in period of amorphous carbon film could be drastically shortened to 22 ± 5 cycles by fabricating a 5-nm graphene nanocrystallite cap layer. The cap layer gave rise to rapid formation of graphene nanocrystallized transfer film, which responds to the short run-in period. We found two key factors for the rapid formation of transfer film. Firstly, the cap layer had lower wear resistance than the amorphous carbon, severing as a quick-wearing sacrificial layer. Secondly, the anocrystallization of transfer film was mainly due to friction-induced restructuring of graphene nanocrystallite but not friction-induced heat. In addition, the friction test of amorphous carbon film covered with multilayer graphene micro-flakes also verified that friction-induced rapid restructuring of graphene sheets at sliding surfaces resulted in short run-in period.