Low friction of graphene nanocrystallite embedded carbon nitride coatings prepared with MCECR plasma sputteringViews [3991] Delivery time :2017-12-08 09:59:08

Low friction of graphene nanocrystallite embedded carbon nitride coatings prepared with MCECR plasma sputtering

Surface & Coatings Technology 332 (2017) 153–160

Pengfei Wang, Weiqiang Zhang, Dongfeng Diao*

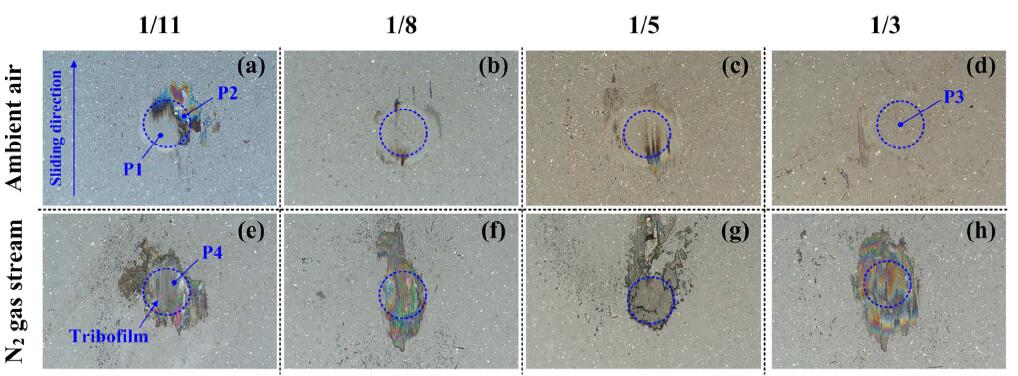

Graphene nanocrystallite embedded carbon nitride (GNECN) coatings were fabricated with the mirror confinement electron  cyclotron resonance (MCECR) plasma sputtering system under low energy electron irradiation at various N2/Ar ratios. N2/Ar ratio was clarified to be an effective deposition parameter for tailoring the composition and structure of the GNECN coatings. It was observed that the deposition rate, N/C atomic ratio, internal stress, surface roughness, and scratch depth of the prepared GNECN coatings change greatly with the increasing N2/Ar ratio from 1/11 to 1/3. Graphene nanocrystallite was clearly identified in the amorphous carbon nitride structure from the analyses of TEM, XPS, and Raman spectroscopy. Moreover, the friction behavior of the GNECN coatings sliding against Si3N4 balls in both ambient air and N2 gas stream showed less dependency on the N2/Ar ratio. Specifically, high friction coefficients ranging from 0.10 to 0.15 were obtained in ambient air, whereas, stable and low friction coefficients of< 0.05 were achieved in N2 gas stream. Optical images and Raman spectra of the worn surfaces on the Si3N4 balls and GNECN coatings suggested that a homogeneous tribofilm on the mating ball surface together with the generation and evolution of the nano-size graphene structure in the GNECN coating are the key points in achieving stable and low friction coefficients of< 0.05 of the GNECN coatings in N2 gas stream. Finally, it was argued that the combination of low energy electron irradiation and nitrogen atom incorporation in the MCECR plasma sputtering system results in the embedding of soft graphene nanocrystallites into hard carbon nitride matrix, providing a beneficial architecture for achieving stable and low friction coefficients of GNECN coatings in N2 gas stream.

cyclotron resonance (MCECR) plasma sputtering system under low energy electron irradiation at various N2/Ar ratios. N2/Ar ratio was clarified to be an effective deposition parameter for tailoring the composition and structure of the GNECN coatings. It was observed that the deposition rate, N/C atomic ratio, internal stress, surface roughness, and scratch depth of the prepared GNECN coatings change greatly with the increasing N2/Ar ratio from 1/11 to 1/3. Graphene nanocrystallite was clearly identified in the amorphous carbon nitride structure from the analyses of TEM, XPS, and Raman spectroscopy. Moreover, the friction behavior of the GNECN coatings sliding against Si3N4 balls in both ambient air and N2 gas stream showed less dependency on the N2/Ar ratio. Specifically, high friction coefficients ranging from 0.10 to 0.15 were obtained in ambient air, whereas, stable and low friction coefficients of< 0.05 were achieved in N2 gas stream. Optical images and Raman spectra of the worn surfaces on the Si3N4 balls and GNECN coatings suggested that a homogeneous tribofilm on the mating ball surface together with the generation and evolution of the nano-size graphene structure in the GNECN coating are the key points in achieving stable and low friction coefficients of< 0.05 of the GNECN coatings in N2 gas stream. Finally, it was argued that the combination of low energy electron irradiation and nitrogen atom incorporation in the MCECR plasma sputtering system results in the embedding of soft graphene nanocrystallites into hard carbon nitride matrix, providing a beneficial architecture for achieving stable and low friction coefficients of GNECN coatings in N2 gas stream.